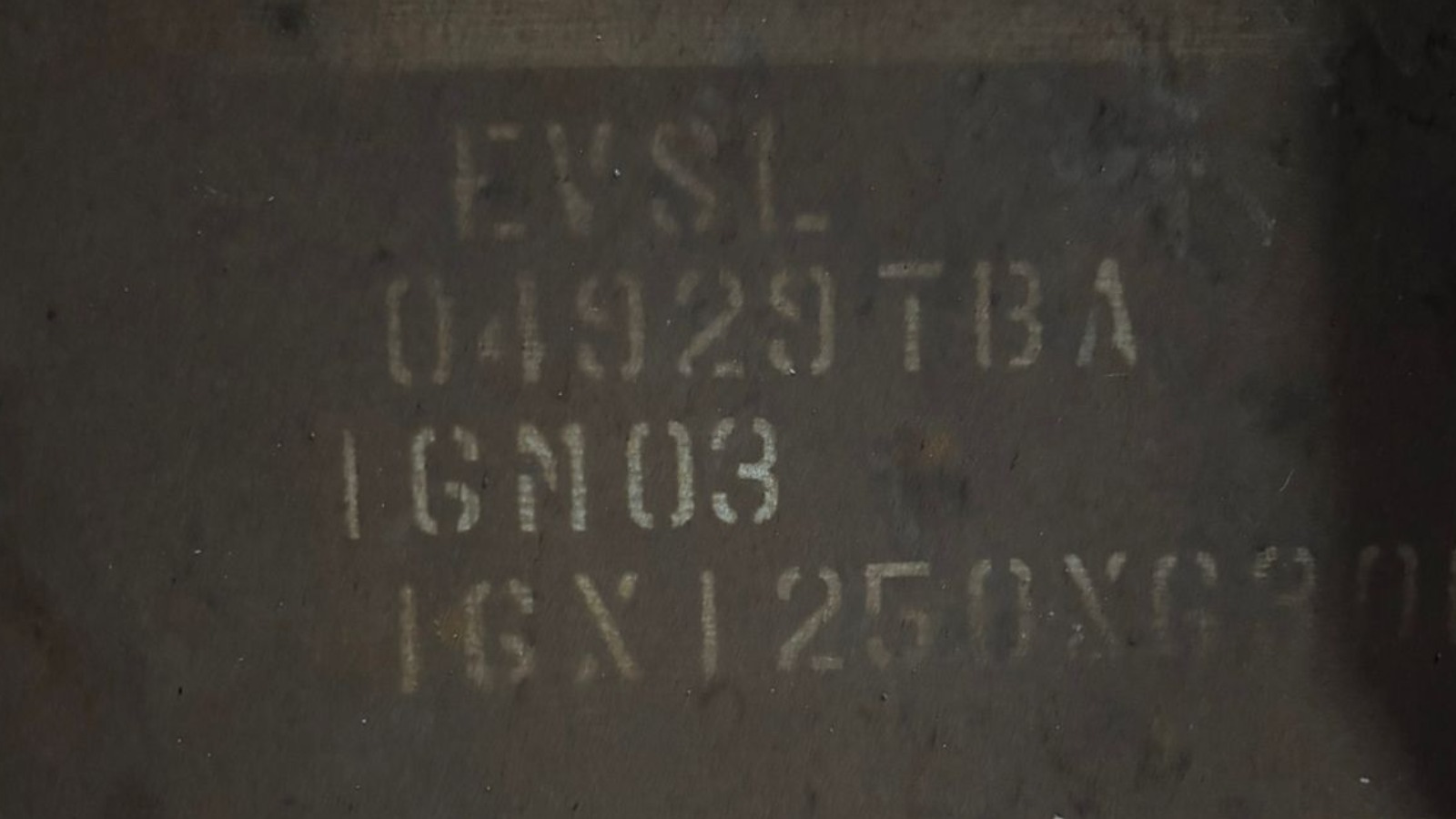

16Mo3 – Chrome-Moly Pressure Vessel Steel for Elevated Temperature Service 16Mo3 is a low-alloy pressure vessel steel with added molybdenum (0.3%), designed for use at elevated temperatures. It is widely used in applications where resistance to creep, heat, and oxidation is essential. With excellent thermal strength, fabrication properties, and cost-efficiency, 16Mo3 is commonly used in boilers, heat exchangers, and piping systems operating in harsh thermal environments. As per EN 10028-2 standards, 16Mo3 has become a go-to material across power generation, refineries, and petrochemical industries for mid-range temperature applications. Key Benefits: High Temperature Resistance: Designed for service temperatures up to ~600°C, maintaining good mechanical performance under thermal stress. Creep and Oxidation Resistance: Molybdenum addition enhances resistance to long-term heat-induced deformation and corrosion from hot gases and steam. Good Weldability and Fabrication: Suitable for standard welding processes with correct heat treatment; easily formed and machined for complex vessel construction. Reliable in Moderate Pressure Systems: Ideal for pressure equipment operating under both internal pressure and elevated temperature conditions. Mechanical Properties Overview: Property 16Mo3 (Typical Values) Yield Strength ≥ 220–275 MPa (depending on thickness) Tensile Strength 440–590 MPa Elongation ≥ 22% Max Service Temp Up to ~600°C Typical Applications: Boilers and superheaters in power plants Heat exchangers and pressure vessels High-temperature piping in chemical plants Refineries and process heaters handling hot gas and steam Summary: 16Mo3 offers a strong balance of thermal resistance, mechanical integrity, and fabrication flexibility, making it a reliable choice for medium-temperature pressure systems. It remains a widely used material for engineers designing equipment that operates continuously under heat and pressure in energy and process industries.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sambhavpipesfittings.com/latest-update/16mo3-chrome-moly-pressure-vessel-steel-for-ele/156

16Mo3 – Chrome-Moly Pressure Vessel Steel for Ele...

2025-06-03T04:24:57

16Mo3 – Chrome-Moly Pressure Vessel Steel for Elevated Temperature Service 16Mo3 is a low-alloy pressure vessel steel with added molybdenum (0.3%), designed for use at elevated temperatures. It is widely used in applications where resistance to creep, heat, and oxidation is essential. With excellent thermal strength, fabrication properties, and cost-efficiency, 16Mo3 is commonly used in boilers, heat exchangers, and piping systems operating in harsh thermal environments. As per EN 10028-2 standards, 16Mo3 has become a go-to material across power generation, refineries, and petrochemical industries for mid-range temperature applications. Key Benefits: High Temperature Resistance: Designed for service temperatures up to ~600°C, maintaining good mechanical performance under thermal stress. Creep and Oxidation Resistance: Molybdenum addition enhances resistance to long-term heat-induced deformation and corrosion from hot gases and steam. Good Weldability and Fabrication: Suitable for standard welding processes with correct heat treatment; easily formed and machined for complex vessel construction. Reliable in Moderate Pressure Systems: Ideal for pressure equipment operating under both internal pressure and elevated temperature conditions. Mechanical Properties Overview: Property 16Mo3 (Typical Values) Yield Strength ≥ 220–275 MPa (depending on thickness) Tensile Strength 440–590 MPa Elongation ≥ 22% Max Service Temp Up to ~600°C Typical Applications: Boilers and superheaters in power plants Heat exchangers and pressure vessels High-temperature piping in chemical plants Refineries and process heaters handling hot gas and steam Summary: 16Mo3 offers a strong balance of thermal resistance, mechanical integrity, and fabrication flexibility, making it a reliable choice for medium-temperature pressure systems. It remains a widely used material for engineers designing equipment that operates continuously under heat and pressure in energy and process industries.

2025-06-03T04:24:57

Keywords

- goto material

- process industries

- operates continuously

- reliable choice

- strong balance

- hot gases

- service temperatures

- petrochemical industries

- costefficiency 16mo3

- elevated temperatures

- internal pressure

- fabrication suitable

- creep heat

- boilers heat exchangers

- mediumtemperature pressure systems

- pressure equipment operating

- fabrication flexibility making

- thermal stress creep

- engineers designing equipment

- chemical plants refineries

- standard welding processes

- steam good weldability

- longterm heatinduced deformation

- power generation refineries

- harsh thermal environments

- piping systems operating

Submit Your Enquiry