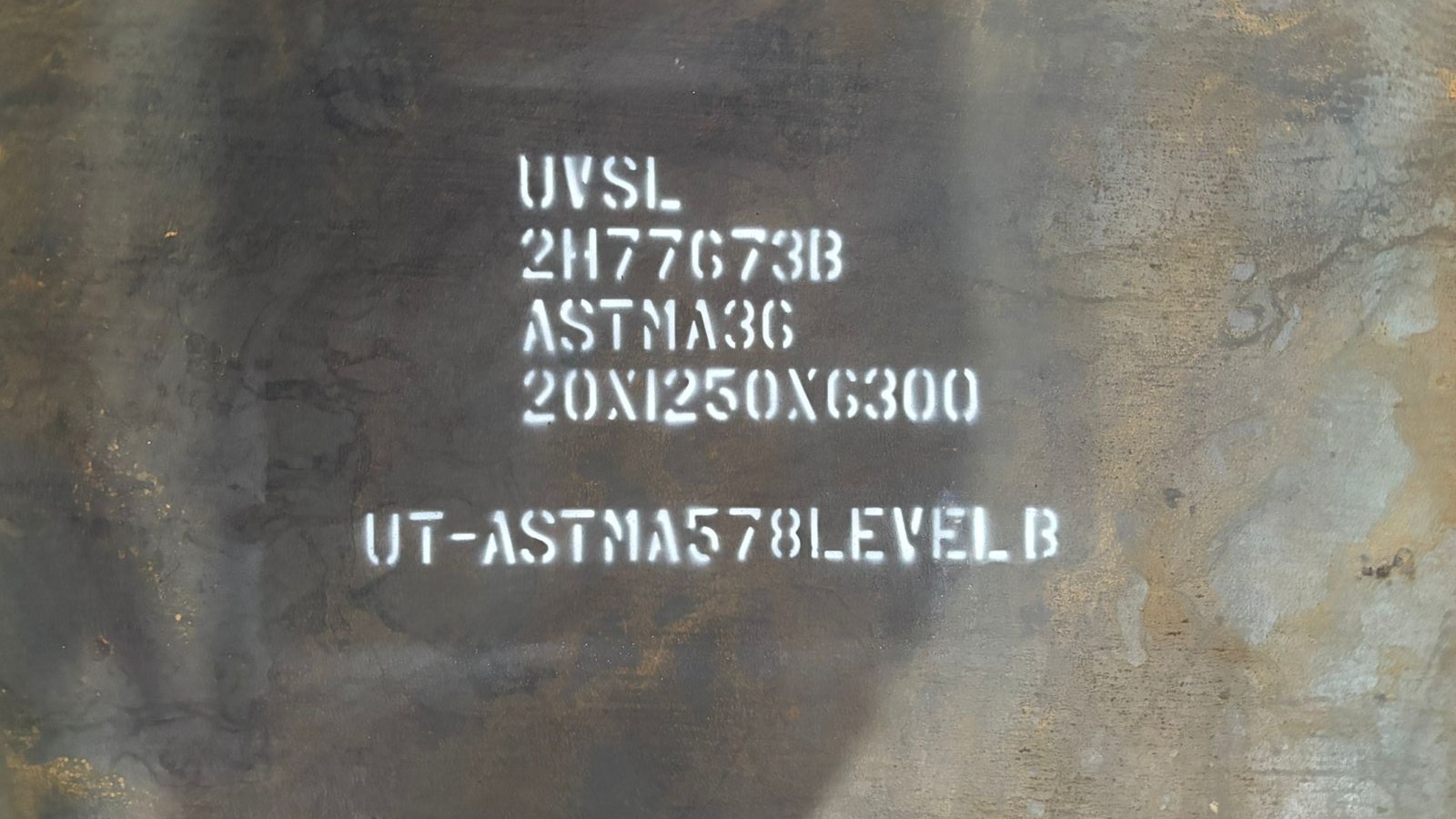

ASTM A36 (Standard Carbon Steel Plate for Structural Applications) ASTM A36 is one of the most commonly used carbon steel grades in the construction and fabrication industries. Known for its excellent weldability, ductility, and versatility, A36 steel is primarily used in structural applications that require moderate strength and ease of fabrication. With a minimum yield strength of 250 MPa (36 ksi), it is widely applied in bridges, buildings, and general-purpose engineering components. This low-carbon steel grade meets the standards set by the American Society for Testing and Materials (ASTM) and performs reliably under room temperature conditions without complex alloying. Key Features: Yield strength of 250 MPa (36 ksi) suitable for general structural work Outstanding weldability and formability using conventional processes Good machinability, ideal for cutting, drilling, and forming Widely available and cost-effective for large-scale fabrication projects Typical Mechanical Properties: Property ASTM A36 Yield Strength ≥ 250 MPa (36 ksi) Tensile Strength 400–550 MPa (58–80 ksi) Elongation ≥ 20% Impact Resistance Fair (not typically impact-rated) Weldability Excellent Common Applications: Structural steel components in bridges, buildings, and sheds Base plates, angles, channels, I-beams, and H-beams General fabrication including tanks, frames, and platforms Machinery parts, automotive frames, and tool supports Pipes, steel sections, and reinforcements Summary: ASTM A36 is a reliable, general-purpose carbon steel grade known for its balance of strength, affordability, and easy workability. Its widespread use across construction and manufacturing makes it a cornerstone material for a broad range of engineering and structural projects.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sambhavpipesfittings.com/latest-update/astm-a36-standard-carbon-steel-plate-for-structur/163

ASTM A36 (Standard Carbon Steel Plate for Structur...

2025-06-09T04:45:40

ASTM A36 (Standard Carbon Steel Plate for Structural Applications) ASTM A36 is one of the most commonly used carbon steel grades in the construction and fabrication industries. Known for its excellent weldability, ductility, and versatility, A36 steel is primarily used in structural applications that require moderate strength and ease of fabrication. With a minimum yield strength of 250 MPa (36 ksi), it is widely applied in bridges, buildings, and general-purpose engineering components. This low-carbon steel grade meets the standards set by the American Society for Testing and Materials (ASTM) and performs reliably under room temperature conditions without complex alloying. Key Features: Yield strength of 250 MPa (36 ksi) suitable for general structural work Outstanding weldability and formability using conventional processes Good machinability, ideal for cutting, drilling, and forming Widely available and cost-effective for large-scale fabrication projects Typical Mechanical Properties: Property ASTM A36 Yield Strength ≥ 250 MPa (36 ksi) Tensile Strength 400–550 MPa (58–80 ksi) Elongation ≥ 20% Impact Resistance Fair (not typically impact-rated) Weldability Excellent Common Applications: Structural steel components in bridges, buildings, and sheds Base plates, angles, channels, I-beams, and H-beams General fabrication including tanks, frames, and platforms Machinery parts, automotive frames, and tool supports Pipes, steel sections, and reinforcements Summary: ASTM A36 is a reliable, general-purpose carbon steel grade known for its balance of strength, affordability, and easy workability. Its widespread use across construction and manufacturing makes it a cornerstone material for a broad range of engineering and structural projects.

2025-06-09T04:45:40

Keywords

- structural projects

- broad range

- cornerstone material

- manufacturing makes

- easy workability

- tanks frames

- forming widely

- cutting drilling

- performs reliably

- materials astm

- american society

- standards set

- bridges buildings

- widely applied

- structural applications

- fabrication industries

- strength affordability

- hbeams general fabrication

- generalpurpose engineering components

- minimum yield strength

- require moderate strength

- room temperature conditions

- versatility a36 steel

- excellent weldability ductility

- carbon steel grades

Submit Your Enquiry