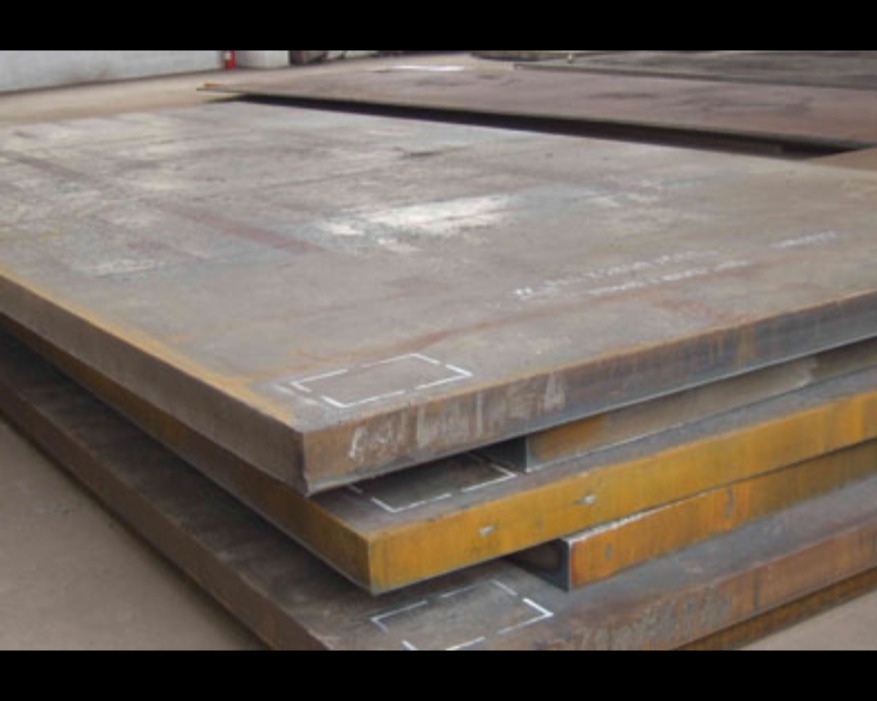

NM 400 / 450 / 500 are abrasion-resistant (AR) steel plates developed in China, widely recognized for their excellent wear resistance and structural performance. These plates are suitable for industries where high-strength materials are essential to combat severe wear and impact, especially in mining, construction, and heavy machinery applications. Key Characteristics: Hardness Range: NM 400: 360–440 Brinell Hardness Number (BHN) NM 450: 420–480 BHN NM 500: 470–530 BHN Wear Resistance: Engineered to perform in highly abrasive environments, significantly reducing material loss and surface degradation. High Strength: Strong mechanical properties provide excellent impact resistance and structural durability under heavy loads. Good Workability: Despite high hardness, NM plates offer decent machinability, bendability, and weldability with proper procedures. Chemical Composition: Typical alloying elements used in NM series plates include: Carbon (C) Manganese (Mn) Silicon (Si) Chromium (Cr) Nickel (Ni) Boron (B) Additional trace elements to enhance performance and stability Applications: Mining equipment (e.g., dump truck bodies, liners, buckets) Earthmoving machinery Cement and aggregate processing equipment Agricultural and forestry machines Chutes, conveyors, hoppers, and wear parts Recycling and crushing equipment Benefits: Long service life under abrasive and high-impact conditions Reduced maintenance frequency and cost Lighter and stronger components for efficient operation Available in multiple hardness levels for tailored applications Production Process: NM plates are manufactured using a quenching and tempering process, ensuring a tough core and a hard, wear-resistant surface for maximum longevity in extreme environments. Sizes and Availability: NM plates are supplied in a variety of standard and custom dimensions to meet specific industrial requirements. Common thicknesses range from 3 mm to 80 mm or more, depending on grade and supplier.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sambhavpipesfittings.com/latest-update/nm-400-450-500-are-abrasion-resistant-ar-ste/145

NM 400 / 450 / 500 are abrasion-resistant (AR) ste...

2025-05-29T05:11:25

NM 400 / 450 / 500 are abrasion-resistant (AR) steel plates developed in China, widely recognized for their excellent wear resistance and structural performance. These plates are suitable for industries where high-strength materials are essential to combat severe wear and impact, especially in mining, construction, and heavy machinery applications. Key Characteristics: Hardness Range: NM 400: 360–440 Brinell Hardness Number (BHN) NM 450: 420–480 BHN NM 500: 470–530 BHN Wear Resistance: Engineered to perform in highly abrasive environments, significantly reducing material loss and surface degradation. High Strength: Strong mechanical properties provide excellent impact resistance and structural durability under heavy loads. Good Workability: Despite high hardness, NM plates offer decent machinability, bendability, and weldability with proper procedures. Chemical Composition: Typical alloying elements used in NM series plates include: Carbon (C) Manganese (Mn) Silicon (Si) Chromium (Cr) Nickel (Ni) Boron (B) Additional trace elements to enhance performance and stability Applications: Mining equipment (e.g., dump truck bodies, liners, buckets) Earthmoving machinery Cement and aggregate processing equipment Agricultural and forestry machines Chutes, conveyors, hoppers, and wear parts Recycling and crushing equipment Benefits: Long service life under abrasive and high-impact conditions Reduced maintenance frequency and cost Lighter and stronger components for efficient operation Available in multiple hardness levels for tailored applications Production Process: NM plates are manufactured using a quenching and tempering process, ensuring a tough core and a hard, wear-resistant surface for maximum longevity in extreme environments. Sizes and Availability: NM plates are supplied in a variety of standard and custom dimensions to meet specific industrial requirements. Common thicknesses range from 3 mm to 80 mm or more, depending on grade and supplier.

2025-05-29T05:11:25

Keywords

- 80 mm

- 3 mm

- custom dimensions

- maximum longevity

- tough core

- efficient operation

- stronger components

- cost lighter

- enhance performance

- structural durability

- mining construction

- highstrength materials

- structural performance

- availability nm plates

- nm series plates

- extreme environments sizes

- hard wearresistant surface

- tempering process ensuring

- multiple hardness levels

- wear parts recycling

- additional trace elements

- combat severe wear

- excellent wear resistance

- china widely recognized

Submit Your Enquiry