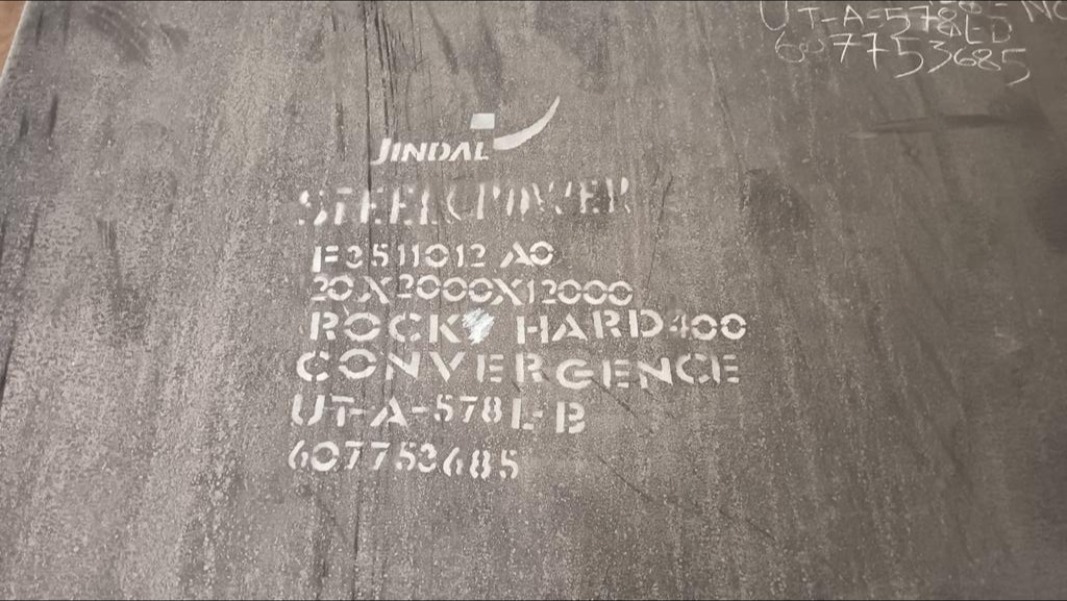

Rockhard 400/450/500 is a type of Abrasion Resistant (AR) steel plate, engineered to deliver superior wear resistance, strength, and toughness for heavy-duty applications exposed to extreme wear and impact. Key Characteristics: Hardness: Rockhard 400: 360–440 Brinell Hardness Number (BHN) Rockhard 450: 420–480 BHN Rockhard 500: 470–530 BHN Abrasion Resistance: Exceptional wear resistance under harsh working conditions, ideal for high-friction environments. Strength: High tensile strength, offering durability and long service life. Weldability: Weldable with proper procedures; preheating and post-weld heat treatment may be required to avoid cracking and maintain mechanical properties. Chemical Composition: Rockhard AR steel plates typically contain: Carbon (C) Manganese (Mn) Chromium (Cr) Nickel (Ni) Boron (B) Other alloying elements depending on the grade Applications: Earthmoving and mining equipment Construction machinery and attachments Agricultural tools and components Truck beds, dump bodies, and liners Industrial wear parts (e.g., crushers, screens) Silos, hoppers, and chutes Benefits: Extended equipment life Lower downtime and maintenance costs High performance in abrasive conditions Consistent hardness and toughness across the plate Manufacturing: Rockhard steel plates are manufactured using a quenching and tempering process, ensuring a tough core with a hard, wear-resistant surface for optimal performance. Dimensions and Thickness: Available in a wide range of thicknesses and dimensions tailored to customer specifications and application needs.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry