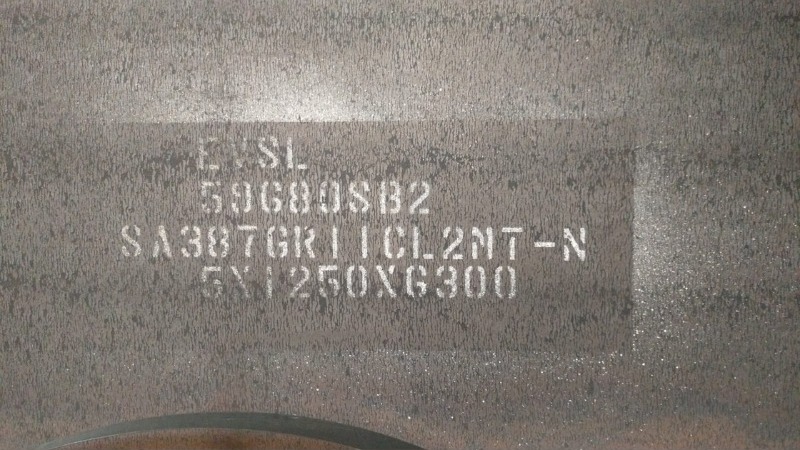

SA 387 GR 11 CL 1 / CL 2 – Chrome-Moly Alloy Steel for Elevated Temperature Pressure Systems SA 387 Grade 11 Class 1 and Class 2 are alloy steel plates combining 1.25% chromium and 0.5% molybdenum, engineered for use in high-temperature pressure vessels, heat exchangers, and thermal processing units. These plates deliver a dependable blend of oxidation resistance, moderate creep strength, and fabrication versatility, making them ideal for a wide range of thermal and industrial environments. Class 1 suits general high-temperature duties, while Class 2 offers enhanced tensile strength for higher-stress conditions. Key Benefits: Thermal Stability and Performance: Designed for operation in environments up to ~600°C, maintaining strength and resisting deformation over time. Corrosion and Oxidation Protection: Cr-Mo alloying ensures reliability in steam service, hydrogen atmospheres, and mildly corrosive conditions. Dual Strength Classes: Class 1 is suitable for standard pressure equipment, while Class 2 is tailored for heavier mechanical loads. Efficient Weldability and Workability: Supports conventional welding and forming methods with proper heat management, reducing fabrication complexity. Mechanical Properties Snapshot: Property SA 387 Gr 11 Cl 1 SA 387 Gr 11 Cl 2 Yield Strength ≥ 205 MPa ≥ 220 MPa Tensile Strength 415–585 MPa 515–690 MPa Elongation ≥ 20% ≥ 18% Max Service Temp Up to ~600°C Up to ~600°C Common Applications: Steam drums, thermal reactors, and pressure vessels Boilers and superheaters in power plants Equipment for refineries and petrochemical facilities Piping systems carrying high-temperature fluids or gases Summary: SA 387 GR 11 CL 1 / CL 2 plates offer reliable strength and resistance for elevated-temperature applications. With good mechanical integrity and adaptability in fabrication, they remain a dependable choice for thermal processing, chemical, and power generation systems where material performance is critical.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sambhavpipesfittings.com/latest-update/sa-387-gr-11-cl-1-cl-2-chrome-moly-alloy-steel/154

SA 387 GR 11 CL 1 / CL 2 – Chrome-Moly Alloy Steel...

2025-06-02T04:25:37

SA 387 GR 11 CL 1 / CL 2 – Chrome-Moly Alloy Steel for Elevated Temperature Pressure Systems SA 387 Grade 11 Class 1 and Class 2 are alloy steel plates combining 1.25% chromium and 0.5% molybdenum, engineered for use in high-temperature pressure vessels, heat exchangers, and thermal processing units. These plates deliver a dependable blend of oxidation resistance, moderate creep strength, and fabrication versatility, making them ideal for a wide range of thermal and industrial environments. Class 1 suits general high-temperature duties, while Class 2 offers enhanced tensile strength for higher-stress conditions. Key Benefits: Thermal Stability and Performance: Designed for operation in environments up to ~600°C, maintaining strength and resisting deformation over time. Corrosion and Oxidation Protection: Cr-Mo alloying ensures reliability in steam service, hydrogen atmospheres, and mildly corrosive conditions. Dual Strength Classes: Class 1 is suitable for standard pressure equipment, while Class 2 is tailored for heavier mechanical loads. Efficient Weldability and Workability: Supports conventional welding and forming methods with proper heat management, reducing fabrication complexity. Mechanical Properties Snapshot: Property SA 387 Gr 11 Cl 1 SA 387 Gr 11 Cl 2 Yield Strength ≥ 205 MPa ≥ 220 MPa Tensile Strength 415–585 MPa 515–690 MPa Elongation ≥ 20% ≥ 18% Max Service Temp Up to ~600°C Up to ~600°C Common Applications: Steam drums, thermal reactors, and pressure vessels Boilers and superheaters in power plants Equipment for refineries and petrochemical facilities Piping systems carrying high-temperature fluids or gases Summary: SA 387 GR 11 CL 1 / CL 2 plates offer reliable strength and resistance for elevated-temperature applications. With good mechanical integrity and adaptability in fabrication, they remain a dependable choice for thermal processing, chemical, and power generation systems where material performance is critical.

2025-06-02T04:25:37

Keywords

- class 2

- material performance

- dependable choice

- elevatedtemperature applications

- forming methods

- time corrosion

- resisting deformation

- performance designed

- wide range

- dependable blend

- plates deliver

- 05 molybdenum engineered

- 600c maintaining strength

- fabrication versatility making

- thermal processing chemical

- thermal processing units

- power generation systems

- good mechanical integrity

- power plants equipment

- pressure vessels boilers

- standard pressure equipment

Submit Your Enquiry