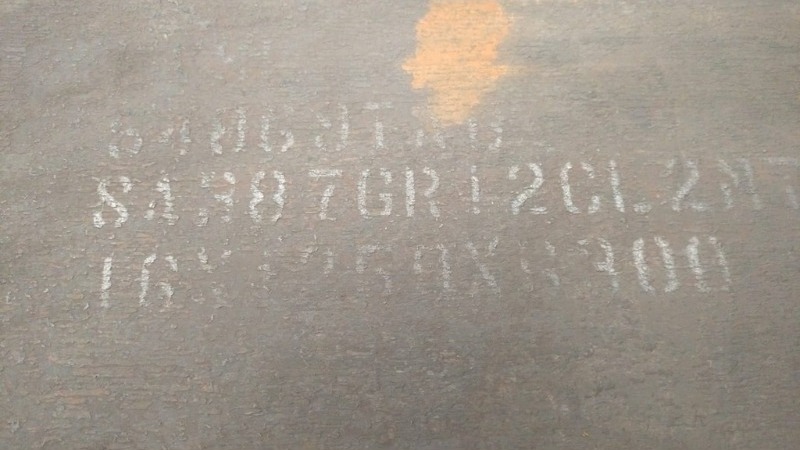

SA 387 GR 12 CL 1 / CL 2 – Chrome-Moly Steel for Reliable High-Temperature Pressure Service SA 387 Grade 12 Class 1 and Class 2 plates are alloy steels containing approximately 1% chromium and 0.5% molybdenum, developed for pressure applications involving moderate to high temperatures. These plates are known for their thermal stability, oxidation resistance, and dependable mechanical strength, making them a preferred choice for boilers, heat exchangers, and petrochemical vessels. While Class 1 meets the requirements of general elevated-temperature use, Class 2 is suitable for environments demanding greater tensile and creep strength. Key Benefits: Thermal Strength and Longevity: Designed to operate efficiently at temperatures approaching ~600°C, maintaining strength and structural integrity over extended periods. Resistance to Oxidation and Mild Corrosion: Effective in hot steam or mildly reactive chemical environments, thanks to Cr-Mo alloying. Class Variants for Flexible Design: Choose Class 1 for standard high-temp pressure work or Class 2 for more demanding applications with higher mechanical stresses. Good Weldability and Machinability: Compatible with common welding practices and easy to fabricate when proper preheat/post-weld treatments are applied. Mechanical Properties Snapshot: Property SA 387 Gr 12 Cl 1 SA 387 Gr 12 Cl 2 Yield Strength ≥ 205 MPa ≥ 220 MPa Tensile Strength 415–585 MPa 515–690 MPa Elongation ≥ 20% ≥ 18% Max Service Temp Up to ~600°C Up to ~600°C Typical Applications: High-pressure steam vessels and drums Thermal processing units and reformers Refinery exchangers and preheaters Piping systems for hot gas and steam flow Summary: With its proven performance under heat and pressure, SA 387 GR 12 CL 1 / CL 2 is a versatile material for critical pressure components in power, refining, and chemical industries. Its solid fabrication properties and dual strength classes provide both flexibility and durability for engineers designing high-performance systems.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sambhavpipesfittings.com/latest-update/sa-387-gr-12-cl-1-cl-2-chrome-moly-steel-for-r/155

SA 387 GR 12 CL 1 / CL 2 – Chrome-Moly Steel for R...

2025-06-02T04:26:23

SA 387 GR 12 CL 1 / CL 2 – Chrome-Moly Steel for Reliable High-Temperature Pressure Service SA 387 Grade 12 Class 1 and Class 2 plates are alloy steels containing approximately 1% chromium and 0.5% molybdenum, developed for pressure applications involving moderate to high temperatures. These plates are known for their thermal stability, oxidation resistance, and dependable mechanical strength, making them a preferred choice for boilers, heat exchangers, and petrochemical vessels. While Class 1 meets the requirements of general elevated-temperature use, Class 2 is suitable for environments demanding greater tensile and creep strength. Key Benefits: Thermal Strength and Longevity: Designed to operate efficiently at temperatures approaching ~600°C, maintaining strength and structural integrity over extended periods. Resistance to Oxidation and Mild Corrosion: Effective in hot steam or mildly reactive chemical environments, thanks to Cr-Mo alloying. Class Variants for Flexible Design: Choose Class 1 for standard high-temp pressure work or Class 2 for more demanding applications with higher mechanical stresses. Good Weldability and Machinability: Compatible with common welding practices and easy to fabricate when proper preheat/post-weld treatments are applied. Mechanical Properties Snapshot: Property SA 387 Gr 12 Cl 1 SA 387 Gr 12 Cl 2 Yield Strength ≥ 205 MPa ≥ 220 MPa Tensile Strength 415–585 MPa 515–690 MPa Elongation ≥ 20% ≥ 18% Max Service Temp Up to ~600°C Up to ~600°C Typical Applications: High-pressure steam vessels and drums Thermal processing units and reformers Refinery exchangers and preheaters Piping systems for hot gas and steam flow Summary: With its proven performance under heat and pressure, SA 387 GR 12 CL 1 / CL 2 is a versatile material for critical pressure components in power, refining, and chemical industries. Its solid fabrication properties and dual strength classes provide both flexibility and durability for engineers designing high-performance systems.

2025-06-02T04:26:23

Keywords

- class 2

- class 2 plates

- class 1 meets

- chemical industries

- power refining

- versatile material

- proven performance

- hot gas

- machinability compatible

- demanding applications

- structural integrity

- operate efficiently

- longevity designed

- general elevatedtemperature

- petrochemical vessels

- preferred choice

- high temperatures

- 05 molybdenum developed

- approximately 1 chromium

- alloy steels

- hot steam

- boilers heat exchangers

- steam flow summary

- solid fabrication properties

- critical pressure components

- preheaters piping systems

- reformers refinery exchangers

- proper preheatpostweld treatments

- common welding practices

- mild corrosion effective

- extended periods resistance

Submit Your Enquiry