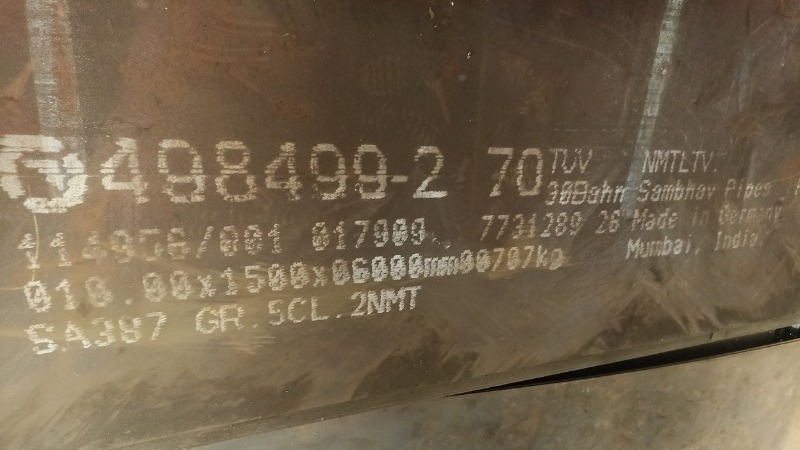

SA 387 GR 5 CL 1 / CL 2 – Chromium-Molybdenum Alloy Steel Plate for High-Temperature Service SA 387 Grade 5 Class 1 and Class 2 are pressure vessel quality alloy steel plates designed for high-temperature service. These plates are alloyed with chromium (5%) and molybdenum (0.5%) to deliver excellent resistance to heat, oxidation, and corrosion, especially in environments involving elevated temperatures and pressures such as petrochemical, power generation, and refinery industries. The key difference between Class 1 and Class 2 lies in their tensile strength and temperature resistance, with Class 2 offering higher mechanical strength. Key Highlights: Excellent High-Temperature Performance: Designed to retain strength and structural integrity in environments exceeding 400°C (752°F). Enhanced Corrosion and Oxidation Resistance: Chromium and molybdenum improve resistance to hydrogen attack, sulfide corrosion, and oxidation in harsh atmospheres. Superior Weldability and Fabrication Properties: Suitable for welding and forming with standard techniques used in pressure vessel manufacturing. Two Classes for Versatility: Class 1: Lower tensile strength; suitable for moderate stress applications. Class 2: Higher tensile strength; ideal for more demanding conditions. Mechanical Properties Overview: Property SA 387 Gr 5 Cl 1 SA 387 Gr 5 Cl 2 Yield Strength ≥ 205 MPa ≥ 220 MPa Tensile Strength 415–585 MPa 515–690 MPa Elongation ≥ 20% ≥ 18% Temperature Resistance Up to ~600°C (dependent on conditions) Up to ~600°C Typical Applications: Petrochemical and Refining Equipment: Reactors, distillation columns, heat exchangers, and catalytic converters. Power Generation Systems: Boilers, steam drums, and pressure vessels operating under elevated temperatures. Oil & Gas Industry: Pressure-retaining parts in sour service and hydrogen-containing environments. Thermal Processing Plants: Components exposed to cyclical thermal loading and high stress. Conclusion: SA 387 GR 5 CL 1/2 plates offer dependable performance in high-pressure, high-temperature conditions. With excellent creep resistance, corrosion protection, and weldability, they’re a trusted choice for critical components in energy, oil & gas, and chemical processing industries.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sambhavpipesfittings.com/latest-update/sa-387-gr-5-cl-1-cl-2-chromium-molybdenum-allo/150

SA 387 GR 5 CL 1 / CL 2 – Chromium-Molybdenum Allo...

2025-05-31T04:40:02

SA 387 GR 5 CL 1 / CL 2 – Chromium-Molybdenum Alloy Steel Plate for High-Temperature Service SA 387 Grade 5 Class 1 and Class 2 are pressure vessel quality alloy steel plates designed for high-temperature service. These plates are alloyed with chromium (5%) and molybdenum (0.5%) to deliver excellent resistance to heat, oxidation, and corrosion, especially in environments involving elevated temperatures and pressures such as petrochemical, power generation, and refinery industries. The key difference between Class 1 and Class 2 lies in their tensile strength and temperature resistance, with Class 2 offering higher mechanical strength. Key Highlights: Excellent High-Temperature Performance: Designed to retain strength and structural integrity in environments exceeding 400°C (752°F). Enhanced Corrosion and Oxidation Resistance: Chromium and molybdenum improve resistance to hydrogen attack, sulfide corrosion, and oxidation in harsh atmospheres. Superior Weldability and Fabrication Properties: Suitable for welding and forming with standard techniques used in pressure vessel manufacturing. Two Classes for Versatility: Class 1: Lower tensile strength; suitable for moderate stress applications. Class 2: Higher tensile strength; ideal for more demanding conditions. Mechanical Properties Overview: Property SA 387 Gr 5 Cl 1 SA 387 Gr 5 Cl 2 Yield Strength ≥ 205 MPa ≥ 220 MPa Tensile Strength 415–585 MPa 515–690 MPa Elongation ≥ 20% ≥ 18% Temperature Resistance Up to ~600°C (dependent on conditions) Up to ~600°C Typical Applications: Petrochemical and Refining Equipment: Reactors, distillation columns, heat exchangers, and catalytic converters. Power Generation Systems: Boilers, steam drums, and pressure vessels operating under elevated temperatures. Oil & Gas Industry: Pressure-retaining parts in sour service and hydrogen-containing environments. Thermal Processing Plants: Components exposed to cyclical thermal loading and high stress. Conclusion: SA 387 GR 5 CL 1/2 plates offer dependable performance in high-pressure, high-temperature conditions. With excellent creep resistance, corrosion protection, and weldability, they’re a trusted choice for critical components in energy, oil & gas, and chemical processing industries.

2025-05-31T04:40:02

Keywords

- class 1

- class 2

- molybdenum 05

- chromium 5

- class 2 lies

- critical components

- trusted choice

- weldability theyre

- sour service

- 600c dependent

- standard techniques

- structural integrity

- retain strength

- tensile strength

- key difference

- heat oxidation

- refinery industries

- hightemperature service

- temperature resistance

- oxidation resistance chromium

- highpressure hightemperature conditions

- molybdenum improve resistance

- chemical processing industries

- deliver excellent resistance

- energy oil gas

- cyclical thermal loading

- pressure vessels operating

- pressure vessel manufacturing

- fabrication properties suitable

- petrochemical power generation

Submit Your Enquiry