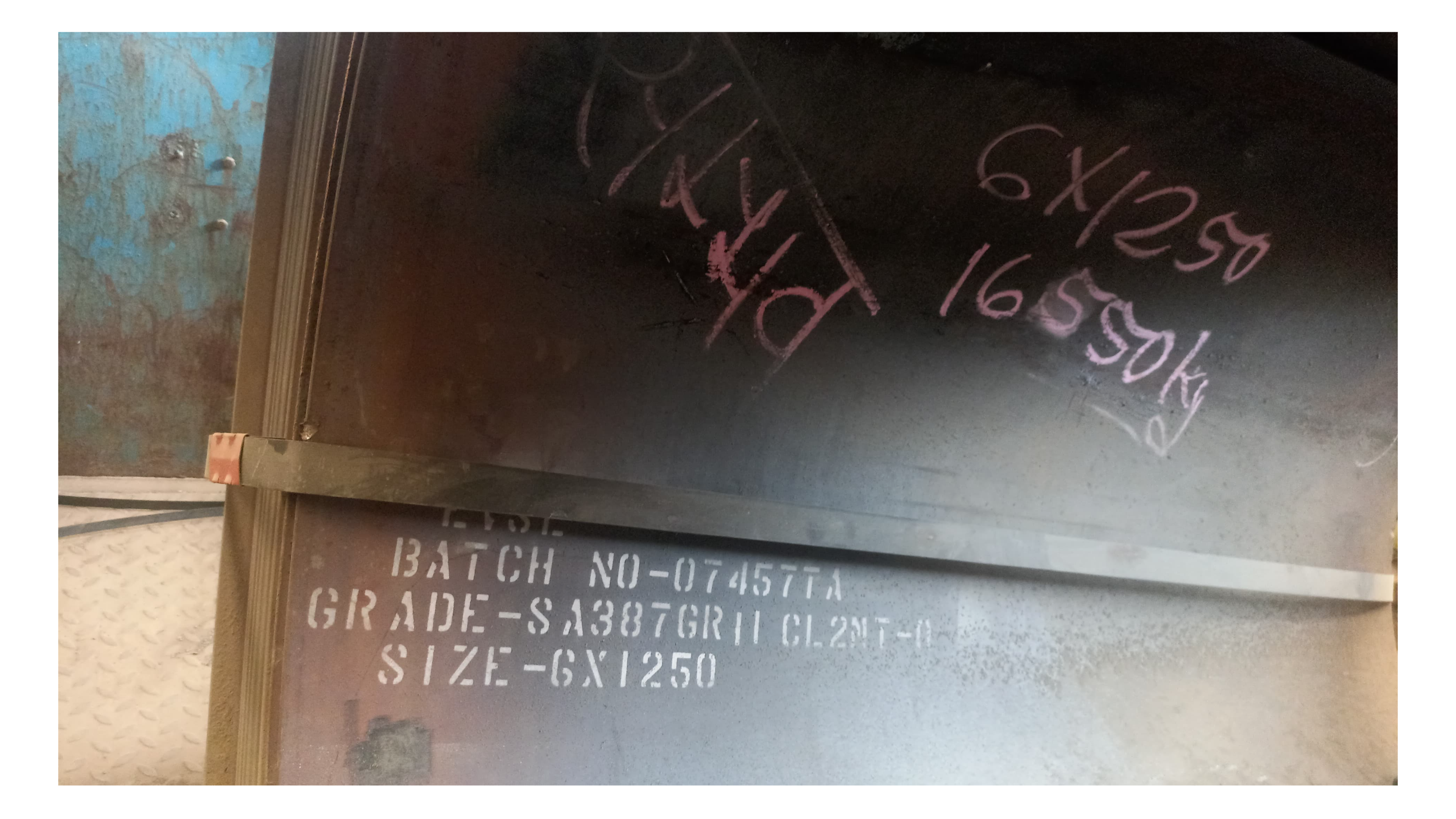

SA 387 steel: General Requirements - Standard: ASME SA 387/ASTM A 387 - Specification for Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum - Fabrication: Hot rolled, cold rolled, or heat treated Chemical Composition - Carbon: 0.05-0.19% (Grade 2, 12), 0.05-0.17% (Grade 11), 0.10-0.20% (Grade 22), 0.15-0.25% (Grade 5, 9) - Manganese: 0.30-0.60% (Grade 2, 12), 0.40-0.65% (Grade 11), 0.30-0.60% (Grade 22), 0.30-0.60% (Grade 5, 9) - Phosphorus: 0.025% max (all grades) - Sulfur: 0.025% max (all grades) - Silicon: 0.50% max (Grade 2, 12), 0.50-1.00% (Grade 11), 0.20-0.50% (Grade 22), 0.50-1.00% (Grade 5, 9) - Chromium: 0.50-1.00% (Grade 2, 12), 1.00-1.50% (Grade 11), 1.90-2.60% (Grade 22), 4.00-6.00% (Grade 5), 8.00-10.00% (Grade 9) - Molybdenum: 0.45-0.65% (Grade 2, 12), 0.45-0.65% (Grade 11), 0.90-1.10% (Grade 22), 0.45-0.65% (Grade 5, 9) Mechanical Properties - Tensile Strength: - Grade 2, 12: 415-585 MPa (60-85 ksi) - Grade 11: 415-585 MPa (60-85 ksi) - Grade 22: 485-655 MPa (70-95 ksi) - Grade 5, 9: 515-690 MPa (75-100 ksi) - Yield Strength: - Grade 2, 12: 205-275 MPa (30-40 ksi) - Grade 11: 205-275 MPa (30-40 ksi) - Grade 22: 240-310 MPa (35-45 ksi) - Grade 5, 9: 240-310 MPa (35-45 ksi) - Elongation: 18-22% (all grades) Impact Properties - Impact Test Temperature: -20°C (-30°F) (Grade 2, 12), 0°C (32°F) (Grade 11), -20°C (-30°F) (Grade 22), 0°C (32°F) (Grade 5, 9) - Impact Energy: - Grade 2, 12: 20-40 J (15-30 ft-lb) - Grade 11: 20-40 J (15-30 ft-lb) - Grade 22: 25-50 J (18-37 ft-lb) - Grade 5, 9: 25-50 J (18-37 ft-lb) Dimensions and Tolerances - Thickness: 5-100 mm (0.2-3.9 in) - Width: 1000-2500 mm (39.4-98.4 in) - Length: 2000-12000 mm (78.7-472.4 in) - Tolerances: As per ASME SA 20/ASTM A 20 Certification and Marking - Certification: ASME SA 387/ASTM A 387 - Marking: As per ASME SA 20/ASTM A 20 Applications - Pressure vessels - Boilers - Heat exchangers - Pipework - Oil, gas, and petrochemical industries Note: This specification is a general overview and may not be applicable to every situation. It's essential to consult the relevant ASME and ASTM standards for specific requirements.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sambhavpipesfittings.com/latest-update/sa-387-steel-general-requirements-standard-as/131

SA 387 steel: General Requirements - Standard: AS...

2025-03-13T10:54:57

SA 387 steel: General Requirements - Standard: ASME SA 387/ASTM A 387 - Specification for Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum - Fabrication: Hot rolled, cold rolled, or heat treated Chemical Composition - Carbon: 0.05-0.19% (Grade 2, 12), 0.05-0.17% (Grade 11), 0.10-0.20% (Grade 22), 0.15-0.25% (Grade 5, 9) - Manganese: 0.30-0.60% (Grade 2, 12), 0.40-0.65% (Grade 11), 0.30-0.60% (Grade 22), 0.30-0.60% (Grade 5, 9) - Phosphorus: 0.025% max (all grades) - Sulfur: 0.025% max (all grades) - Silicon: 0.50% max (Grade 2, 12), 0.50-1.00% (Grade 11), 0.20-0.50% (Grade 22), 0.50-1.00% (Grade 5, 9) - Chromium: 0.50-1.00% (Grade 2, 12), 1.00-1.50% (Grade 11), 1.90-2.60% (Grade 22), 4.00-6.00% (Grade 5), 8.00-10.00% (Grade 9) - Molybdenum: 0.45-0.65% (Grade 2, 12), 0.45-0.65% (Grade 11), 0.90-1.10% (Grade 22), 0.45-0.65% (Grade 5, 9) Mechanical Properties - Tensile Strength: - Grade 2, 12: 415-585 MPa (60-85 ksi) - Grade 11: 415-585 MPa (60-85 ksi) - Grade 22: 485-655 MPa (70-95 ksi) - Grade 5, 9: 515-690 MPa (75-100 ksi) - Yield Strength: - Grade 2, 12: 205-275 MPa (30-40 ksi) - Grade 11: 205-275 MPa (30-40 ksi) - Grade 22: 240-310 MPa (35-45 ksi) - Grade 5, 9: 240-310 MPa (35-45 ksi) - Elongation: 18-22% (all grades) Impact Properties - Impact Test Temperature: -20°C (-30°F) (Grade 2, 12), 0°C (32°F) (Grade 11), -20°C (-30°F) (Grade 22), 0°C (32°F) (Grade 5, 9) - Impact Energy: - Grade 2, 12: 20-40 J (15-30 ft-lb) - Grade 11: 20-40 J (15-30 ft-lb) - Grade 22: 25-50 J (18-37 ft-lb) - Grade 5, 9: 25-50 J (18-37 ft-lb) Dimensions and Tolerances - Thickness: 5-100 mm (0.2-3.9 in) - Width: 1000-2500 mm (39.4-98.4 in) - Length: 2000-12000 mm (78.7-472.4 in) - Tolerances: As per ASME SA 20/ASTM A 20 Certification and Marking - Certification: ASME SA 387/ASTM A 387 - Marking: As per ASME SA 20/ASTM A 20 Applications - Pressure vessels - Boilers - Heat exchangers - Pipework - Oil, gas, and petrochemical industries Note: This specification is a general overview and may not be applicable to every situation. It's essential to consult the relevant ASME and ASTM standards for specific requirements.

2025-03-13T10:54:57

Submit Your Enquiry