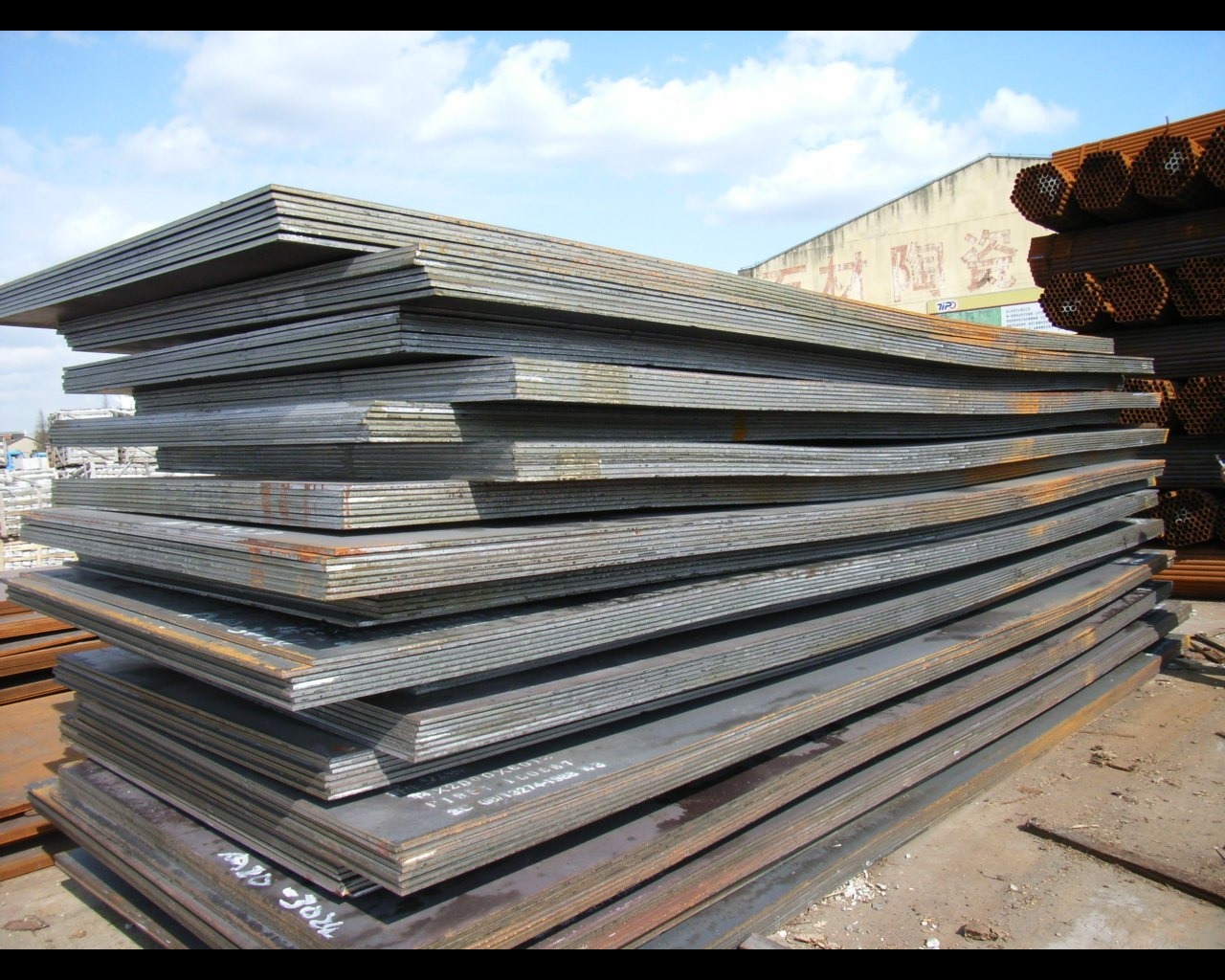

Weather-Resistant Steel Plates – Corrosion Protection Built to Last Weather-Resistant Steel Plates are specially alloyed steels designed to resist atmospheric corrosion better than ordinary carbon steel. Popularly known under trade names like Corten Steel (Corten A/B), these plates form a protective oxide layer, or patina, when exposed to weather. This layer acts as a barrier that significantly slows down future corrosion, eliminating the need for painting in most cases. The unique chemical composition of weathering steel includes elements like copper, chromium, nickel, and phosphorus, which enhance its corrosion resistance in open-air environments. It’s an ideal material for structures that demand aesthetics, strength, and long-term durability. Key Features: Exceptional resistance to weather-induced corrosion Forms a stable, self-healing rust-like appearance (patina) Requires little to no maintenance after installation Good weldability and formability Suitable for both structural and decorative applications Chemical Composition Snapshot (Typical – Corten A): Element Content (%) Copper 0.25 – 0.55 Chromium 0.50 – 1.25 Nickel up to 0.65 Phosphorus up to 0.15 Carbon ≤ 0.12 Mechanical Properties: Property Corten A Corten B Yield Strength 340–345 MPa 345–355 MPa Tensile Strength 470–630 MPa 485–620 MPa Elongation ≥ 20% ≥ 19% Common Applications: Architectural cladding, facades, and sculptures Bridges, railcars, and shipping containers Outdoor furniture, planters, and screens Industrial structures in marine/coastal environments Chimney stacks and weathering steel poles Summary: Weather-resistant steel plates provide a natural, maintenance-free barrier to rust, blending industrial performance with visual appeal. Their longevity and rugged finish make them a popular choice in construction, infrastructure, and artistic installations where exposure to the elements is constant.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Weather-Resistant Steel Plates – Corrosion Prot...

2025-06-17T04:49:57

Weather-Resistant Steel Plates – Corrosion Protection Built to Last Weather-Resistant Steel Plates are specially alloyed steels designed to resist atmospheric corrosion better than ordinary carbon steel. Popularly known under trade names like Corten Steel (Corten A/B), these plates form a protective oxide layer, or patina, when exposed to weather. This layer acts as a barrier that significantly slows down future corrosion, eliminating the need for painting in most cases. The unique chemical composition of weathering steel includes elements like copper, chromium, nickel, and phosphorus, which enhance its corrosion resistance in open-air environments. It’s an ideal material for structures that demand aesthetics, strength, and long-term durability. Key Features: Exceptional resistance to weather-induced corrosion Forms a stable, self-healing rust-like appearance (patina) Requires little to no maintenance after installation Good weldability and formability Suitable for both structural and decorative applications Chemical Composition Snapshot (Typical – Corten A): Element Content (%) Copper 0.25 – 0.55 Chromium 0.50 – 1.25 Nickel up to 0.65 Phosphorus up to 0.15 Carbon ≤ 0.12 Mechanical Properties: Property Corten A Corten B Yield Strength 340–345 MPa 345–355 MPa Tensile Strength 470–630 MPa 485–620 MPa Elongation ≥ 20% ≥ 19% Common Applications: Architectural cladding, facades, and sculptures Bridges, railcars, and shipping containers Outdoor furniture, planters, and screens Industrial structures in marine/coastal environments Chimney stacks and weathering steel poles Summary: Weather-resistant steel plates provide a natural, maintenance-free barrier to rust, blending industrial performance with visual appeal. Their longevity and rugged finish make them a popular choice in construction, infrastructure, and artistic installations where exposure to the elements is constant.

2025-06-17T04:49:57

Keywords

- 065 phosphorus

- artistic installations

- construction infrastructure

- popular choice

- visual appeal

- formability suitable

- ideal material

- openair environments

- significantly slows

- trade names

- layer acts

- plates form

- corrosion resistance

- natural maintenancefree barrier

- screens industrial structures

- protective oxide layer

- weatherresistant steel plates

- weatherinduced corrosion forms

- future corrosion eliminating

- resist atmospheric corrosion

- rugged finish make

- sculptures bridges railcars

- installation good weldability

- demand aesthetics strength

- copper chromium nickel

- unique chemical composition

Submit Your Enquiry