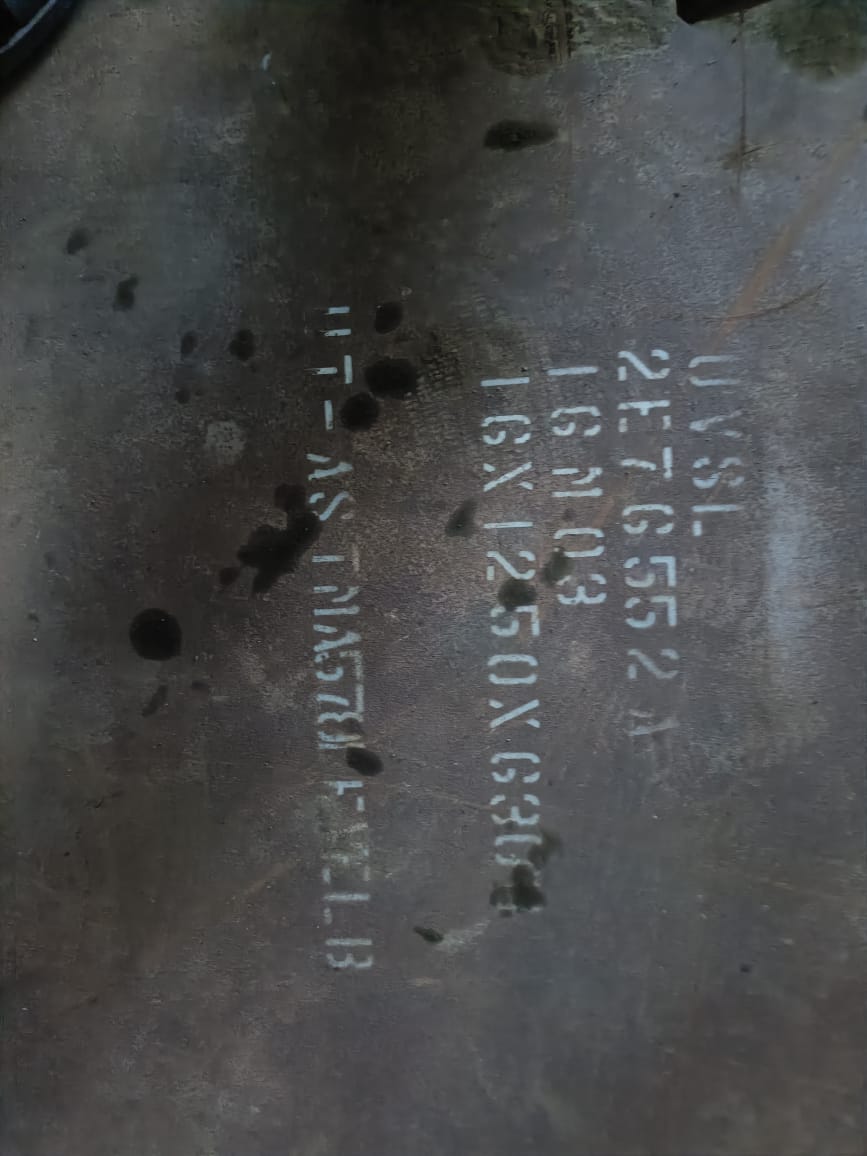

What is SA 387? SA 387 is a specification for alloy steel plates, chromium-molybdenum steel, designed for high-temperature applications. The specification is published by the American Society for Testing and Materials (ASTM). Key Features: 1. Chromium-Molybdenum Steel: SA 387 plates contain 0.5-9.5% chromium and 0.45-1.05% molybdenum, which enhance strength, hardness, and corrosion resistance. 2. High-Temperature Resistance: SA 387 plates can withstand temperatures up to 1200°F (650°C) without losing their strength or integrity. 3. Strength: SA 387 plates exhibit high tensile strength (up to 90, 000 psi) and yield strength (up to 50, 000 psi). 4. Corrosion Resistance: The chromium content provides resistance to corrosion in harsh environments. Applications: 1. Boilers: SA 387 plates are used in boiler components, such as pressure vessels, heat exchangers, and piping. 2. Pressure Vessels: They are used in high-pressure vessels, tanks, and reactors. 3. Power Generation: SA 387 plates are used in power generation equipment, such as turbines and generators. 4. Oil and Gas: They are used in oil and gas industry equipment, such as separators, heaters, and processing vessels. Common Grades: 1. Grade 11: 1.25% chromium, 0.5% molybdenum 2. Grade 12: 1.25% chromium, 0.5% molybdenum (with vanadium) 3. Grade 22: 2.25% chromium, 1% molybdenum 4. Grade 91: 9% chromium, 1% molybdenum (with vanadium) This brief summary should give you a good overview of Alloy Steel Plates SA 387. If you have any specific questions or need further information, feel free to ask!

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sambhavpipesfittings.com/latest-update/what-is-sa-387-sa-387-is-a-specification-for-all/94

What is SA 387? SA 387 is a specification for all...

2024-08-20T09:07:44

What is SA 387? SA 387 is a specification for alloy steel plates, chromium-molybdenum steel, designed for high-temperature applications. The specification is published by the American Society for Testing and Materials (ASTM). Key Features: 1. Chromium-Molybdenum Steel: SA 387 plates contain 0.5-9.5% chromium and 0.45-1.05% molybdenum, which enhance strength, hardness, and corrosion resistance. 2. High-Temperature Resistance: SA 387 plates can withstand temperatures up to 1200°F (650°C) without losing their strength or integrity. 3. Strength: SA 387 plates exhibit high tensile strength (up to 90, 000 psi) and yield strength (up to 50, 000 psi). 4. Corrosion Resistance: The chromium content provides resistance to corrosion in harsh environments. Applications: 1. Boilers: SA 387 plates are used in boiler components, such as pressure vessels, heat exchangers, and piping. 2. Pressure Vessels: They are used in high-pressure vessels, tanks, and reactors. 3. Power Generation: SA 387 plates are used in power generation equipment, such as turbines and generators. 4. Oil and Gas: They are used in oil and gas industry equipment, such as separators, heaters, and processing vessels. Common Grades: 1. Grade 11: 1.25% chromium, 0.5% molybdenum 2. Grade 12: 1.25% chromium, 0.5% molybdenum (with vanadium) 3. Grade 22: 2.25% chromium, 1% molybdenum 4. Grade 91: 9% chromium, 1% molybdenum (with vanadium) This brief summary should give you a good overview of Alloy Steel Plates SA 387. If you have any specific questions or need further information, feel free to ask!

2024-08-20T09:07:44

Keywords

- 000 psi

- 4. Grade

- 3. Grade

- 2. Grade

- 1. Grade

- 9% chromium

- Key Features

- 1% molybdenum

- good overview

- brief summary

- Common Grades

- SA 387 plates

- 2.25% chromium

- 1.25% chromium

- 0.5% molybdenum

- heat exchangers

- 1.05% molybdenum

- chromium content

- pressure vessels

- American Society

- 0.5-9.5% chromium

- boiler components

- specific questions

- processing vessels

- harsh environments

- alloy steel plates

- corrosion resistance

- high tensile strength

- gas industry equipment

- chromium-molybdenum steel

- power generation equipment

- High-Temperature Resistance

- high-temperature applications

Submit Your Enquiry